閱讀 4801 次 清華大學(xué)建筑學(xué)院徐衛(wèi)國教授團(tuán)隊設(shè)計3D打印步行橋上海落成

清華大學(xué)建筑學(xué)院徐衛(wèi)國教授團(tuán)隊設(shè)計3D打印步行橋上海落成

主圖1

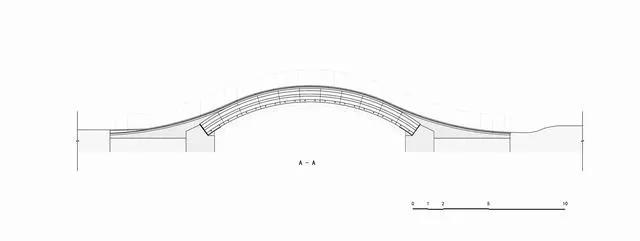

世界最大的混凝土3D打印步行橋在上海落成。由清華大學(xué)(建筑學(xué)院)—中南置地數(shù)字建筑研究中心徐衛(wèi)國教授團(tuán)隊設(shè)計研發(fā)、并與上海智慧灣投資管理公司共同建造。這是一座26.3米長的步行橋,靈感來自中國古代趙州橋的結(jié)構(gòu)方式。

The world’s longest 3D-printed concrete pedestrian bridge has been completed in Shanghai. Designed by Professor Xu Weiguo from theTsinghuaUniversity(SchoolofArchitecture) -ZoinaLandJointResearchCenterfor Digital Architecture, the 26.3-meter-long bridge was inspired by the ancientAnjiBridgeinZhaoxian,China.

主圖2

東南角人視

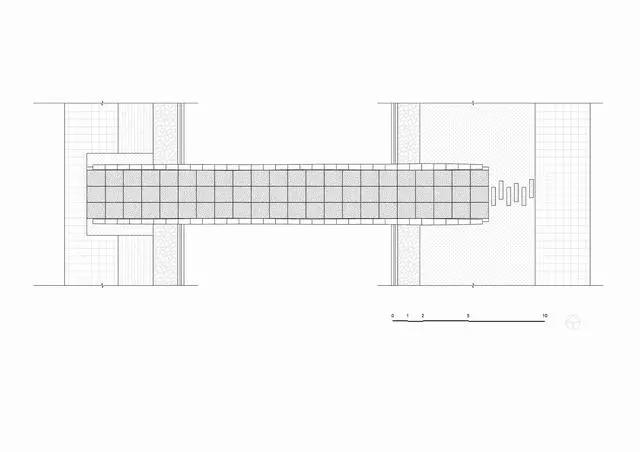

單拱結(jié)構(gòu)采用徐衛(wèi)國教授團(tuán)隊自主開發(fā)的混凝土3D打印系統(tǒng)技術(shù),其具有工作穩(wěn)定性好、打印效率快、成型精度高及可連續(xù)工作等特點。這座步行橋橋的寬度為3.6米,橋欄板采用了形似飄帶的造型,與橋拱一起構(gòu)筑出輕盈優(yōu)雅的體態(tài)橫臥于上海智慧灣池塘之上。

The single-arch structure was created using a 3D printing concrete system developed by Professor Xu Weiguo’s team, integrating digital design, cost efficiency, smart technology, and architectural dynamism. Enclosing the 3.6-meter width, the bridge’s handrails are shaped like flowing ribbons on the arch, creating a light, elegant movement across theShanghaiWisdomBaypond.

西北角人視

東側(cè)俯視

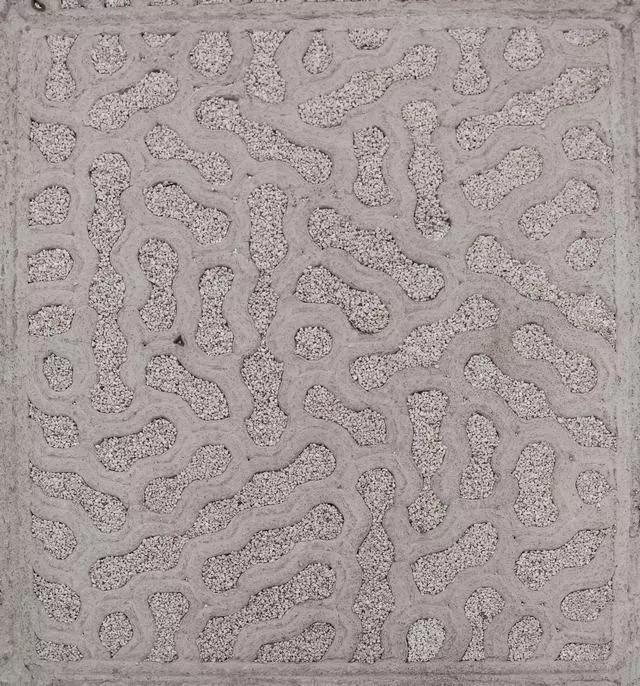

該橋體結(jié)構(gòu)由44塊混凝土3D打印單元組成,而橋欄板分為68塊單元進(jìn)行打印,這些構(gòu)件的打印材料均為聚乙烯纖維混凝土添加多種外加劑組成的復(fù)合材料。

The bridge is constructed of 44 hollowed-out 3D printed concrete units, while the handrails are divided into 68 units. The bridge’s components have been printed from composite materials, containing polyethylene fiber concrete to match the structural performance of conventional materials.

南側(cè)俯視

南立面

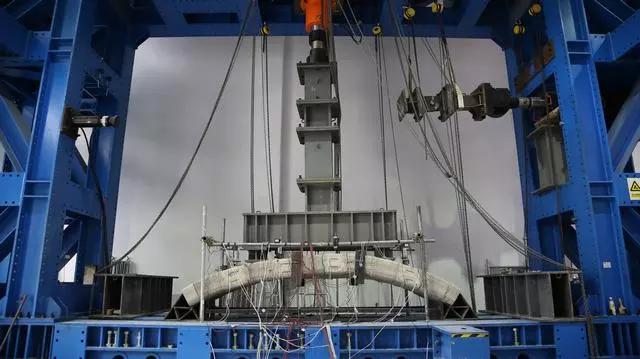

在該橋梁進(jìn)入實際打印施工之前,進(jìn)行了1:4縮尺實材橋梁破壞試驗,其強(qiáng)度可滿足站滿行人的荷載要求。對于實際施工,整體橋梁工程的打印用了兩臺機(jī)器臂3D打印系統(tǒng),共用450小時打印完成全部混凝土構(gòu)件。與同等規(guī)模的橋梁相比,流線型工藝估計節(jié)省了33%,主要歸因于施工未用模板和鋼筋。

The design process involved the construction of a 1:4 scale physical model of the bridge, built to demonstrate the scheme’s viability, and proving that the bridge could hold pedestrians crowding the entire surface. For the actual construction, concrete components for the bridge were printed by two robotic arms, over the course of 450 hours. The streamlined process is estimated to have produced savings of 33% when compared to a more conventional construction process – attributed mainly to the elimination of templates and reinforcing bars.

遠(yuǎn)景

夜景

該橋預(yù)埋有實時監(jiān)測系統(tǒng),包括振弦式應(yīng)力監(jiān)控和高精度應(yīng)變監(jiān)控系統(tǒng),可以即時收集橋梁受力及變形狀態(tài)數(shù)據(jù),對于跟蹤研究新型混凝土材料性能以及打印構(gòu)件的結(jié)構(gòu)力學(xué)性能具有實際作用。

Embedded in the bridge, a real-time monitoring system provides data on vibrating wire stresses and strains. The results will allow for a greater understanding of the practical performance of new concrete materials, and the structural properties of 3D-printed components.

地面局部

扶手局部

該步行橋由清華大學(xué)(建筑學(xué)院)-中南置地數(shù)字建筑研究中心徐衛(wèi)國教授團(tuán)隊設(shè)計研發(fā)、并與上海智慧灣投資管理有限公司共同建造。

The bridge was jointly built with the Shanghai Wisdom Bay Investment Management Company.

打印欄板-copy

欄板局部

混凝土并不是唯一因為3D打印技術(shù)而發(fā)生重大變化的材料。今年早些時候,哥倫比亞大學(xué)推出了一種新的3D打印和掃描新技術(shù),生產(chǎn)出具有真實內(nèi)飾紋理的木材。與此同時,世界上第一座3D打印鋼橋最近在荷蘭設(shè)計周上亮相。

Concrete is not the only material undergoing major change as a result of 3D printing technology. Earlier this year,ColumbiaUniversityunveiled a new technique for 3D printing and scanning, producing a timber lookalike with an authentic interior grain. Meanwhile, the world’s first 3D-printed steel bridge was recently unveiled at Dutch Design Week.

打印過程

打印過程-橋面1

打印過程-橋面2

結(jié)構(gòu)試驗

平面

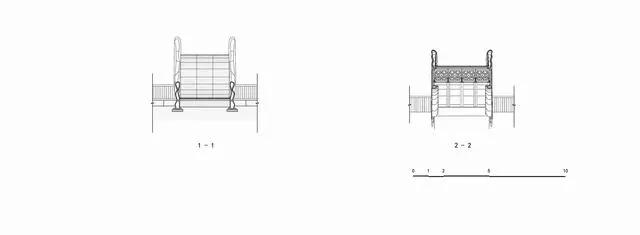

剖面-長

剖面-短

建筑師:清華大學(xué)(建筑學(xué)院)-中南置地數(shù)字建筑研究中心

地點:上海

設(shè)計團(tuán)隊:徐衛(wèi)國 孫晨煒 高遠(yuǎn) 張志齡 文徑網(wǎng)絡(luò)設(shè)計整理

原標(biāo)題:3D打印步行橋

(本文來源:清華大學(xué)建筑學(xué)院網(wǎng) 文徑網(wǎng)絡(luò)數(shù)據(jù)中心:劉紅娟 尹維維 編輯 劉真 方俊 審核)

特別提示:本頁信息來自網(wǎng)絡(luò),如有版權(quán)及知識產(chǎn)權(quán)問題請聯(lián)系刪除。

聯(lián)系我們...

聯(lián)系我們...  圓弧車道施工時標(biāo)高控制的等分直...

圓弧車道施工時標(biāo)高控制的等分直...  新技術(shù)IDITI 法濕陷性黃土地基處...

新技術(shù)IDITI 法濕陷性黃土地基處...  漢長安城遺址保護(hù)區(qū)安置及開發(fā)住...

漢長安城遺址保護(hù)區(qū)安置及開發(fā)住...  高校基礎(chǔ)設(shè)施建設(shè)BOT項目研究...

高校基礎(chǔ)設(shè)施建設(shè)BOT項目研究...  陜西土木建筑網(wǎng)簡介...

陜西土木建筑網(wǎng)簡介...  級配壓實砂石墊層在西安地區(qū)的施...

級配壓實砂石墊層在西安地區(qū)的施...  低碳城市建設(shè)在西安的探索與實踐...

低碳城市建設(shè)在西安的探索與實踐...  淺談中國古代建筑材料與建筑的發(fā)...

淺談中國古代建筑材料與建筑的發(fā)...  漢長安城遺址保護(hù)區(qū)內(nèi)安置及開發(fā)...

漢長安城遺址保護(hù)區(qū)內(nèi)安置及開發(fā)...  柴油發(fā)電機(jī)房的火災(zāi)危險性類別分...

柴油發(fā)電機(jī)房的火災(zāi)危險性類別分...  陜西重型機(jī)械廠改造規(guī)劃設(shè)計...

陜西重型機(jī)械廠改造規(guī)劃設(shè)計...  世界十位著名建筑師介紹及其作品...

世界十位著名建筑師介紹及其作品...  西安紡織城藝術(shù)區(qū)改造設(shè)計(一)...

西安紡織城藝術(shù)區(qū)改造設(shè)計(一)...  寶雞市青少年科技活動中心設(shè)計...

寶雞市青少年科技活動中心設(shè)計...